Finding Top Chinese Manufacturers for Stainless Steel Baby Tableware?

Sourcing from China can be tricky, right? I remember when I first started, finding reliable suppliers felt like a huge task. You want quality stainless steel baby tableware, but navigating the options can be overwhelming.

To find the best Chinese manufacturers for stainless steel baby tableware, you need to check their certifications carefully. Also, verify their factory compliance and audit reports. Understand their typical Minimum Order Quantities (MOQs) and production lead times. Importantly, take steps to protect your unique designs.

Following these steps will help you find great partners and ensure your products are safe and high-quality. Let's break down what you need to look for.

What certifications should Chinese suppliers hold?

Are you worried about product safety or import problems? Not knowing which certifications your Chinese supplier needs for stainless steel baby tableware can be a real headache. I'll explain the important ones for you.

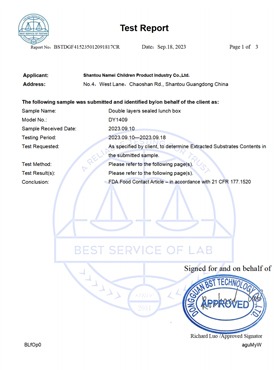

Chinese suppliers for stainless steel baby tableware should have ISO 9001 for quality systems. They also need BSCI for social compliance. For material safety, look for product-specific reports like FDA for the US market or LFGB for Europe.

When you're looking for a supplier for stainless steel baby tableware, certifications are not just pieces of paper. They are proof that the factory meets certain standards. This is super important for baby products because safety is the top priority. As a business like mine, dearya, we ensure our factory meets these standards. We are audited for ISO, FDA, and BSCI compliance. This gives our B2B clients peace of mind.

Key Quality Management Systems: ISO 9001

ISO 9001 is about quality management. This certification shows that a factory has a system to make sure its products are consistently good. It means they have processes for everything, from checking raw materials to inspecting the final products. If a supplier has ISO 9001, it’s a good sign they are serious about quality. This doesn't mean every product will be perfect. But it does mean they have a system to catch problems and fix them. For you, as a buyer, this reduces the risk of getting a bad batch of products. It also shows the factory is organized and professional.

Social Accountability Standards: BSCI

BSCI stands for Business Social Compliance Initiative. This certification is about how the factory treats its workers and the environment. It covers things like fair working hours, safe working conditions, and no child labor. For baby products, this is especially important. Consumers care about where their products come from and how they are made. A BSCI certificate shows that the supplier is committed to ethical production. This can be a strong selling point for your brand. It also aligns with the values of many large companies and brand owners who are our potential customers. They want to be sure their supply chain is clean.

Material Safety Certifications: FDA and LFGB

These certifications relate directly to the safety of the materials used in the baby tableware.

- FDA (Food and Drug Administration): This is mainly for products sold in the United States. It means the materials that touch food are safe and don't release harmful substances. For stainless steel baby tableware, this is crucial. You need to be sure the steel grade is food-safe and there are no harmful coatings or chemicals.

- LFGB (Lebensmittel-, Bedarfsgegenstände- und Futtermittelgesetzbuch): This is a German standard, but it's widely recognized in Europe. It's often considered stricter than FDA requirements. If your supplier has LFGB, it’s a very good sign for product safety. It covers not just the material itself but also that the product won't change the taste or smell of food.

Other certifications might be relevant depending on your specific product or market. For example, EN 14372 is a European standard for children's cutlery and feeding utensils. Always ask potential suppliers for copies of their certificates and check their validity.

Here's a quick comparison:

| Certification | Focus Area | Importance for Baby Tableware | Main Market(s) |

| ISO 9001 | Quality Management Systems | Consistent product quality, reliable processes | Global |

| BSCI | Social Compliance, Ethics | Ethical sourcing, good working conditions, brand reputation | Global, esp. EU |

| FDA | Food Contact Material Safety | Ensures materials are safe for food, prevents harmful leaching | USA |

| LFGB | Food Contact Material Safety | Ensures materials are safe, no taste/odor transfer, often stricter | EU, esp. Germany |

Understanding these certifications helps you choose suppliers who are committed to quality, safety, and ethical practices. This is key for building a reliable supply chain for your stainless steel baby tableware.

How can you verify factory compliance and audit reports?

It's natural to feel a bit unsure about supplier claims. What if those audit reports aren't real? This worry can be stressful, as fake documents could lead to serious issues. I'll guide you through how to check them.

To verify factory compliance and audit reports, always ask for the original, complete documents. Then, check with the organization that issued the report, often through their online database or by contacting them directly. Using a third-party inspection service for on-site checks is also a smart move.

Verifying compliance is a critical step. You can't just take a supplier's word for it, especially when it comes to products for babies. As someone who runs a factory in China, dearya, we welcome this scrutiny. We have our ISO, FDA, and BSCI audits ready for our B2B clients because transparency builds trust. Here’s how you can dig deeper and make sure the reports you see are legitimate and current.

Obtaining Original and Complete Documents

First, don't accept just a summary or a certificate. Ask for the full audit report. A certificate only tells you they passed on a certain date. The full report gives you much more detail. It will show the scope of the audit, the date it was performed, the expiry date, any non-compliance issues found, and the corrective actions taken. Be wary if a supplier is hesitant to share the full report. Legitimate factories are usually transparent about their audit results, even if there were minor issues that have since been fixed. The report should also clearly state the name and address of the audited factory. Make sure this matches the details of the supplier you are dealing with.

Checking with Issuing Agencies

Once you have the report, look for the name of the auditing company or organization that issued it. Common third-party auditors include SGS, Intertek, TÜV SÜD, Bureau Veritas, or specific bodies like BSCI itself. Most reputable auditing firms have online databases where you can verify the authenticity of a report or certificate using its unique number.

- Go to the website of the issuing agency.

- Look for a section like "Verify Certificate" or "Certified Client Directory."

- Enter the certificate or report number.

If you can't find an online verification tool, or if the report isn't listed, try contacting the issuing agency directly. You can usually find contact details on their website. Send them a copy of the report and ask them to confirm its authenticity. This step is very important to avoid being tricked by fake or altered documents.

The Value of Independent On-Site Audits

While existing audit reports are useful, they represent a snapshot in time. Conditions at a factory can change. If you are placing large orders or establishing a long-term partnership, consider commissioning your own third-party audit. This gives you the most up-to-date and unbiased information. You can hire an independent auditing company to visit the factory and check for:

- Quality Management Systems: Do they follow their ISO 9001 procedures?

- Social Compliance: Are working conditions as stated in the BSCI report?

- Production Capacity: Can they actually handle your order volume?

- Specific Requirements: You can also ask the auditors to check for things specific to your product, like the type of stainless steel being used (e.g., 304 or 18/8 grade).

This might seem like an extra cost, but it can save you a lot of money and trouble in the long run. It's an investment in risk management.

Red Flags in Audit Reports and Verification

Be alert for these common red flags:

- Expired Certificates: An old certificate doesn't guarantee current compliance.

- Mismatched Names/Addresses: The factory name or address on the report is different from your supplier's details.

- Poor Quality Scans/Copies: If the document looks altered or is hard to read, ask for a clearer original.

- Too Perfect Reports: Sometimes, a report with absolutely no minor non-conformities can be suspicious, though not always.

- No Contact Details for Auditor: If you can't find a way to contact the auditor, that's a concern.

Here’s a quick guide:

| Verification Step | Action | Why it's Important |

| Request Full Report | Ask for the complete audit document, not just a summary. | Provides detailed findings and context. |

| Identify Issuing Body | Note the name of the auditing company (e.g., SGS, Intertek, BSCI). | Allows you to trace the report's origin. |

| Online Verification | Use the auditor's website to check the report/certificate number. | Quickest way to confirm authenticity. |

| Direct Contact with Issuing Body | Email or call the auditor if online verification is not possible. | Confirms validity if online tools are unavailable. |

| Consider Your Own Third-Party Audit | Hire an independent firm for an on-site inspection. | Provides current, unbiased assessment of the factory. |

By being thorough in verifying compliance, you protect your business, your customers, and your brand reputation. It’s a fundamental part of responsible sourcing.

What are the typical MOQ and lead times from China?

Are you finding it hard to plan your inventory? Uncertainty about Minimum Order Quantities (MOQs) and production lead times from Chinese suppliers can really disrupt your business flow. I'll share some common figures to help you plan better.

Typically, MOQs for stainless steel baby tableware from China are between 1,000 and 3,000 pieces per item or color. Standard production lead times usually run from 30 to 60 days after your sample is approved and the deposit is paid.

Understanding MOQs and lead times is essential for managing your cash flow and meeting your customers' demands. These figures can vary quite a bit from one factory to another, and also depend on the product itself. At dearya, we work with our B2B clients to find workable solutions, as we manage the whole supply chain, including order and logistics management. Let's look at what these terms mean and what influences them.

Understanding Minimum Order Quantities (MOQs)

The MOQ is the smallest number of units a factory is willing to produce in a single production run. Factories have MOQs for several reasons:

- Setup Costs: Each production run involves setting up machines, preparing molds, and configuring production lines. These setup activities have costs. If the order quantity is too small, the factory can't cover these costs and make a profit.

- Raw Material Purchases: Suppliers of raw materials (like stainless steel sheets or coils) also have their own MOQs. A factory needs to order enough raw material to meet these minimums. For stainless steel, this can be a significant factor.

- Efficiency: Producing in larger batches is generally more efficient. Constant small runs can disrupt production flow and increase per-unit costs.

For stainless steel baby tableware, MOQs often range from 1,000 to 3,000 pieces per specific item or design. If you want custom colors or significant modifications, the MOQ might be higher. Some smaller factories or trading companies might offer lower MOQs, but always check if they are the actual manufacturer and if quality will be consistent. Sometimes, a slightly higher MOQ from a reputable factory is a better long-term choice.

Factors Affecting MOQs

Several things can influence a factory's MOQ:

- Product Complexity: Simpler items might have lower MOQs. More complex designs that require special tooling or multiple components usually have higher MOQs.

- Material Type: Stainless steel often has higher purchasing minimums for the factory compared to some plastics. The grade of stainless steel (e.g., 304 vs. 316) can also play a role.

- Customization Level: Standard, off-the-shelf designs may have lower MOQs. Highly customized products, especially those needing new molds, will almost certainly have higher MOQs to cover the development costs. Our factory, for example, has over 100 sets of existing molds, which can sometimes offer flexibility.

- Factory Size and Policy: Large factories might have higher MOQs because their operations are geared towards bigger volumes. Smaller factories might be more flexible but could have limitations in capacity or quality control.

Decoding Production Lead Times

Lead time is the period from when you confirm your order (usually by paying a deposit and approving pre-production samples) until the goods are ready to leave the factory (Ex-Works). For stainless steel baby tableware from China, a typical lead time is 30 to 60 days.

This period includes several stages:

- Raw Material Sourcing: The factory orders and receives the stainless steel and any other components. (5-15 days)

- Tooling/Mold Preparation: If it's a new design requiring new molds, this can add several weeks before mass production begins. (20-40 days for new molds)

- Production Scheduling: Your order is placed into the factory's production queue.

- Manufacturing Process: This includes cutting, stamping, shaping, welding (if any), polishing, and cleaning the stainless steel items. (15-30 days)

- Quality Control and Inspection: In-process and final quality checks are done. (Part of the manufacturing timeline)

- Packaging: Products are packed according to your specifications. (3-5 days)

Variables Impacting Lead Times

Be aware of these factors that can change the lead time:

- Order Volume: Very large orders might take longer, though sometimes they can be expedited if the factory prioritizes them.

- Factory Workload: If the factory is very busy, your order might have to wait longer. Peak seasons, like the months leading up to Chinese New Year or major Western holidays, often mean longer lead times.

- Product Complexity: Complex items take more time to produce.

- Raw Material Availability: Sometimes, specific grades of stainless steel or other components might have longer procurement times.

- Chinese Holidays: Factories close during major holidays like Chinese New Year (usually 1-3 weeks in Jan/Feb) and Golden Week (1 week in Oct). Always factor these into your planning. Delays are common right before and after these long breaks.

- Sample Approval: The clock for lead time usually starts after you approve the pre-production sample. If there are delays in sample approval, the final delivery will also be delayed.

Here's a table summarizing these influences:

| Factor | Impact on MOQ | Impact on Lead Time |

| Product Complexity | Higher for complex items | Longer for complex items |

| Customization | Higher for custom designs (esp. new molds) | Longer if new molds/tooling needed |

| Order Volume | N/A (defines the order itself) | Can be longer for very large orders; or shorter if prioritized |

| Raw Material Availability | Can increase if special materials needed | Can increase if materials are scarce or have long order times |

| Factory Workload/Season | Generally no direct impact | Longer during peak seasons or high factory load |

| Chinese Holidays | N/A | Significant delays around major holidays |

Clear communication with your supplier about MOQs and lead times is essential. Get these details in writing in your purchase order or contract. This helps prevent misunderstandings and allows you to manage your inventory and customer expectations effectively.

How do you protect your design when sourcing in China?

Are you worried that your unique designs for baby tableware could be copied if you manufacture in China? It's a valid concern; losing your intellectual property (IP) is a significant risk for any business. I'll explain some key strategies to protect your hard work.

To protect your design when sourcing in China, use NNN Agreements (Non-Disclosure, Non-Use, Non-Circumvention) tailored for China. Also, register your design patents in China before showcasing them. Working with reputable manufacturers who value long-term partnerships is also key.

Protecting your intellectual property is crucial, especially when you've invested time and money into creating unique designs for your stainless steel baby tableware. Many businesses, including those run by purchasing managers like Jeff Weaver, value design capabilities. As a manufacturer in China (dearya) that specializes in custom designs based on client drawings or samples, we understand the importance of IP. Here’s how you can safeguard your creative assets.

The Reality of "International Patents"

First, it's important to understand that there's no such thing as a truly "international patent" that automatically protects you everywhere. Patent rights are territorial. This means a patent registered in your home country (like the US or a European nation) generally does not offer protection in China. If you want to protect your design in China, you need to secure protection through the Chinese legal system. China operates on a "first-to-file" system for patents and trademarks. This means the first person or company to file for a patent or trademark in China is typically granted the rights, regardless of who first invented or used it elsewhere. So, timely filing is essential.

Securing Design Patents in China

For product designs, a "design patent" (外观设计专利) in China is often the most relevant form of protection. It protects the ornamental or aesthetic aspects of an article, such as its shape, pattern, or color combination.

- File Early: You should file for a design patent in China before you publicly disclose your design anywhere, including showing it to potential manufacturers without an NNN agreement.

- Relatively Affordable and Quick: Compared to invention patents, Chinese design patents are generally less expensive and faster to obtain. The process can take around 6-12 months.

- What it Covers: It gives you the right to prevent others from making, selling, or importing products that use your patented design in China.

Engage a qualified IP lawyer or agent who specializes in Chinese patent law to help you with the application process.

The Power of NNN Agreements

A standard Non-Disclosure Agreement (NDA) that you might use in your home country is often not effective in China. You need an NNN Agreement. This stands for:

- Non-Disclosure: The supplier agrees not to disclose your confidential information.

- Non-Use: The supplier agrees not to use your confidential information for any purpose other than manufacturing your product. This is crucial to prevent them from using your design to make products for themselves or other clients.

- Non-Circumvention: The supplier agrees not to go around you and sell directly to your customers or use your contacts.

Key features of an effective NNN Agreement for China:

- Written in Chinese: It should be in Mandarin Chinese and governed by Chinese law. This makes it enforceable in Chinese courts.

- Specifies Chinese Courts for Disputes: This makes legal action more practical if needed.

- Clear Definition of IP: Clearly define what constitutes your confidential information and design.

- Stipulated Damages: Include a clause for liquidated damages (a pre-agreed sum) for any breach. This makes it easier to claim compensation.

Have this agreement signed before you reveal any sensitive design details to a potential supplier.

Controlling Your Molds and Tooling

If your product requires custom molds or tooling, this is a significant investment and a key part of your IP.

- Mold Ownership: Your manufacturing contract should clearly state that you own the molds, even if the factory produces and stores them.

- Marking Molds: Have the molds physically marked as your property.

- Exclusive Use Agreement: Get a written agreement that the factory will only use the molds to produce products for you and will not use them for any other client.

- Mold Return/Destruction: Your contract should specify what happens to the molds if you stop working with the factory (e.g., they should be returned to you or verifiably destroyed).

Choosing Trustworthy Manufacturing Partners

Legal agreements are important, but your best protection often comes from working with the right partners.

- Reputation Matters: Look for established factories with a good reputation. Factories like ours (dearya) that have experience with international clients and rely on custom orders are less likely to risk their reputation by misusing your IP. We are BSCI, ISO, and FDA audited, which shows a commitment to professional standards.

- Build Relationships: Long-term relationships built on trust can be very effective. A supplier who sees you as a valuable long-term client is less likely to jeopardize that relationship.

- Visit the Factory: If possible, visit the factory. This helps you assess their professionalism and build a personal connection.

Here's a summary of IP protection measures:

| Protection Method | Key Action | Why it's Important in China |

| Design Patent in China | File before disclosure; use a local IP agent. | "First-to-file" system; territorial rights. |

| NNN Agreement | Sign before sharing details; must be in Chinese, under Chinese law. | Standard NDAs are often ineffective; covers non-use. |

| Mold/Tooling Control | Clearly define ownership and usage rights in your contract. | Prevents unauthorized use of your critical production assets. |

| Supplier Due Diligence | Choose reputable factories; check references; build relationships. | Trustworthy partners are less likely to infringe on your IP. |

| Limit Information Sharing | Only share what is necessary at each stage of engagement. | Reduces exposure if a potential partnership doesn't proceed. |

Protecting your designs in China requires a proactive and multi-layered approach. By combining legal safeguards with careful supplier selection, you can significantly reduce the risks and confidently bring your unique stainless steel baby tableware to market.

Managing Your Baby Feeding Tableware Supply Chain from China: How to Ensure Smooth Operations?

Managing Your Baby Feeding Tableware Supply Chain from China: How to Ensure Smooth Operations?

Negotiating Costs for Baby Plates & Cutlery with Chinese Suppliers: How Can You Get the Best Deal?

Negotiating Costs for Baby Plates & Cutlery with Chinese Suppliers: How Can You Get the Best Deal?

Importing FDA-Grade PP & Tritan Kids Cups from China?

Importing FDA-Grade PP & Tritan Kids Cups from China?

What Design Features Make an IP-Themed Bowl Safe for Infants?

What Design Features Make an IP-Themed Bowl Safe for Infants?